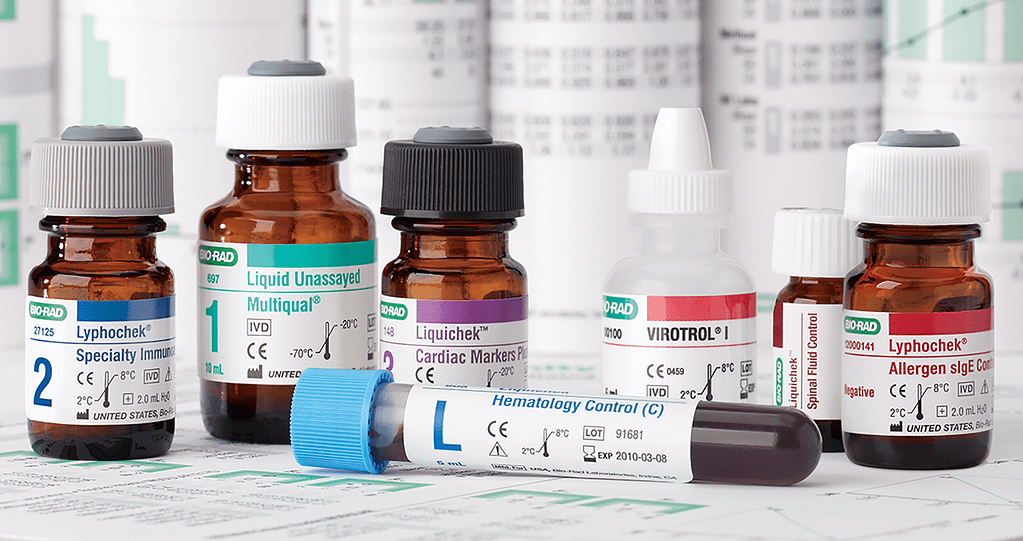

Controls have to be reconstituted as per instructions, given in the pack insert.

Step 1 : Ensure that The first time when you run a control, it is at Room Temperature.

Step 2 : If control is beyond one 2 SD , then rerun the same control after making sure it’s at room temperature.

Step 3 : If still out, then take a freshly reconstituted Control at room temperature and run that.

Step 4 : If Still Out, then Do a Delta Check by running previous day’s sample and compare the Bias ( has to be less than 10 % )

Bias is ( Run 2 – Run 1 ) ÷ ( Run 1 ) and multiplied by 100.

Step 5 : If still out, then Calibrate and rerun the control

Step 6 : If Still out, then Call the Application specialist.

Check Expiry of Reagents on board and instrument factors where necessary. Directly Going for Calibration when controls are out, is an incorrect process.

Make sure Lab mean is set, on 30, 60 & 90 points.

STEPS FOR ROOT CAUSE ANALYSIS

1) Check control material

Change in manufacturer Lot

Improper reconstitution of control

Expired control used

Inadequate storage

2) Check last calibration

Calibration as per frequency

Calibration signals & Variation

3) Check calibration material

Change in manufacturer Lot

Improper reconstitution

Expired calibrator used

Inadequate storage

4) Check Reagents

Change in manufacturer Lot

Improper reconstitution

Expired Reagent

Inadequate storage

Bubbles in reagent

5) Check Instruments

Untrained operator

Inadequate Daily Maintenance

Instrument Preventive maintenance

Instrument calibration

6) Check Trends

Compare data with peer group

Bottle mean/SD & Lab mean/SD Variation